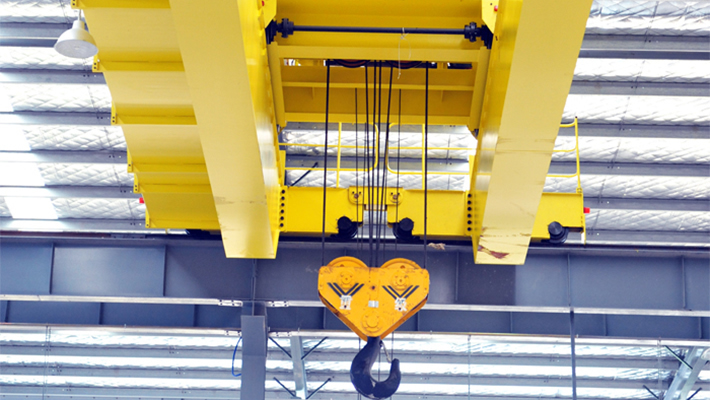

Double Girder Bridge Crane

Advantages of Double Girder Bridge Crane

1. The span structure of the overhead bridge crane is constructed from 2 box girders, 2 box end trucks and runways. The bridge girders and end trucks are connected by rigid welding or bolts. The whole bridge structure can be divided into two parts, thus ensuring easy transportation.

2. The cabin is installed under the girder and internally equipped with electrical control equipment, mainly used for drivers. The cabin is available in open and close structures. For where high temperature, dusty and poisonous environments, the latter structure is a must. If the temperature is higher than 35℃, air conditioning is great choice.

3. The trolley frame is constructed from steel plates by welding. It consists of an electric hoist and a travel mechanism, ensuring stable travel and long service life.

4. The double girder bridge crane boasts 2 outstanding end trucks that apply hydraulic push-rod brake or AC electromagnetic block brake, providing superior braking performance.

5. Thanks to variable frequency control, the bridge crane for chemical industry is remarkably featured with strong overload protection capability. It comes with complete control parameters and can realize perfect control effect by means of automatic detection to motor and parameter optimization.

6. This hoisting machinery is designed taking installation into deep consideration. We carry forward effective design provide the whole control system with complete function, perfect protection and superior performance.

| Lifting Weight | T | 5-550 | |

| Span | m | 10.5~31.5 (Flexible extension) | |

| Lifting height | m | 6-16 (Flexible extension) | |

| Control method | Control in the air | Cabin | Driver cabin with broad vision, toughened glass, ergonomically designed seat and easy operation |

| Control on the ground | Remote control/Pendant | Easy operation, without having to climb; professional driver is unnecessary | |

| Power supply | AC | 3-Phase, AC, 380V, 50HZ | |

| Classification | A5-A6 | ||

| Hoisting mechanism | Hoist type drive | Modular design of motor, reducer, brake, coupling and wire rope reel, compact and safe. | |

| Main electric parts | Schneider or Siemens (Optional) | ||

| Overload protection device | Rotary cam, 4-step adjustable, auto reset, PLC height adjustable system, precise phase-sequence control | ||

| Crane travel limit switch | PU, collision resistance, IR sensor limit protection, etc. | ||

| Steel structure part | Independent design and manufacture; cutting-edge technology and manufacturing strength | ||

| Motor | Best-in-class brand motor in China (optional) | ||

| Electrical control system | Variable frequency control, stator voltage control, PLC with human-machine interface | ||

| Reducer | Best brand in China or SEW, Flanders, etc. | ||

| Wire rope | Wire rope with high strength fiber core or steel core | ||

| Brake | State of the art brand in China or optional | ||

| Hook | Hardened and tempered steel: 34CrMoV; T-class hook is made of alloy steel 34CrMoV4 | ||

| Wire rope reel | Welded reel, rolled from steel plates; light weight, simple structure and high intensity | ||

| Wheel and machining parts | Designed and made by ourselves, bringing you peace in mind | ||